Cylinder production is a process as well as a peace of mind.

Only rigorous production inspection, in order to let you use peace of mind.

The cylinder shall be regarded as defective if the presence of cracks is detected.

It shall also be regarded as defective if the dimensions of any pores or inclusions present reach values considered to pose a threat to safety

9M3 150bar 60L ISO9809-1 37MN Oxygen Tanks Gas Cylinders

ISO9809-1 standard

1. Gas cylinders with maximum tensile strength ≤1100MPa after quenching and tempering;

2, Nominal volume: 0.5-150L;

3, Medium: compressed gas, liquefied gas, dissolved gas;

Operating temperature: -50-65℃.

1、Minimum order quantity: 100 only

2、A meridian section shall be made in the base centre of the cylinder and one of the surfaces thus obtained polished for examination under a magnification of between × 5 and × 10.

3、MADE IN CHINA

We are China’s gas cylinder production factory, product sales:China, Southeast Asia, Middle East, Asia, Africa, Europe, Oceania, America

4、Use cylinders:Our seamless steel cylinders are widely used in industry, medical devices, fire fighting and scientific research

5、In cases where the base is suspected to be plugged, the section shall be etched after the first examination to verify the absence of a plug.

Plugged cylinders shall not be approved. In no case shall the sound thickness (i.e. the thickness with no imperfections) in the base centre be less than the minimum specified thickness

6、The material of seamless gas cylinder, in addition to meeting the basic requirements of material selection, must also have high strength at the same time, with high elongation;

Good heat treatment performance (good quenching performance; Brittle crack tendency is small; Small temper brittleness); High impact toughness value at room temperature and low temperature.

The strength can be improved by adding C, Mn, Cr and other alloying elements and quenching and tempering, but sometimes the elongation and impact toughness value will be reduced. Therefore, the adjustment of strength and elongation will have a great impact on the selection of cylinder material.

In short, chemical composition, heat treatment properties and mechanical properties should be considered in the selection of cylinder materials.

Tips for safe use of gas cylinders:

Do not place the gas cylinder near the heat source. The storage temperature of the gas cylinder should meet the following requirements: Acetylene cylinder should not be higher than 40 ° C, argon cylinder should not be higher than 50 ° C, and oxygen cylinder should not be higher than 60 ° C.

The remaining pressure of acetylene cylinder should not be lower than the following: the remaining pressure is 0.1MPa when the ambient temperature is 0℃ to 15℃, 0.2MPa when the ambient temperature is 15℃ to 25℃, and 0.3MPa when the ambient temperature is 25℃ to 40℃.

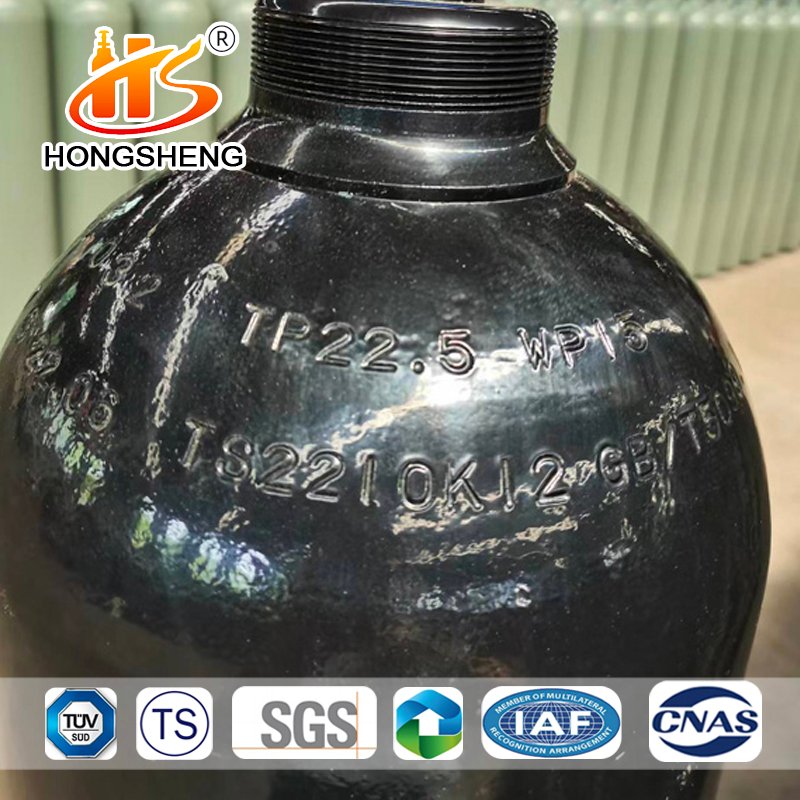

1、 Iso9809-1 production standard; 60 litres; 267mm cylinder outer diameter; 37 mn;Working pressure 150bar; Hydrostatic test pressure 250bar;

2、Alias: Cylinders 60L gas cylinders, 60L Oxygen tanks,60L Oxygen tanks,60L 150bar gas cylinders, 8m3 gas cylinders, 60litre Refuge chamber gas cylinder

3、Oxygen cylinder body height 1320mm; Oxygen cylinder body weight 63.7KG;

Maximum oxygen tank storage is 9m3 (9000 litres);

The minimum design wall thickness of oxygen cylinder is 6.2mm;

Oxygen cylinder mouth thread PZ27.8; 25E; PZ39; 3/4-14 NGT, etc.;

4、60L cylinder can be used for mine refuge chamber: the establishment of underground refuge chamber can effectively improve the safety protection level of the mine and improve the disaster resistance of the mine.

7、60L ISO9809-1 9M3 150bar 37MN Oxygen Tanks Gas Cylinders(ISO9809-1 150BAR)

| Type | Outside Diameter (mm) |

Water Capacity (L) |

Bottle Height (mm) |

Weight (kg) |

Working pressure (Bar) |

Design wall thickness (mm) |

Material Grades |

| ISO267-60.0L-150 | 267 | 60.0 | 1320 | 63.7 | 150 | 6.2 | 37MN |