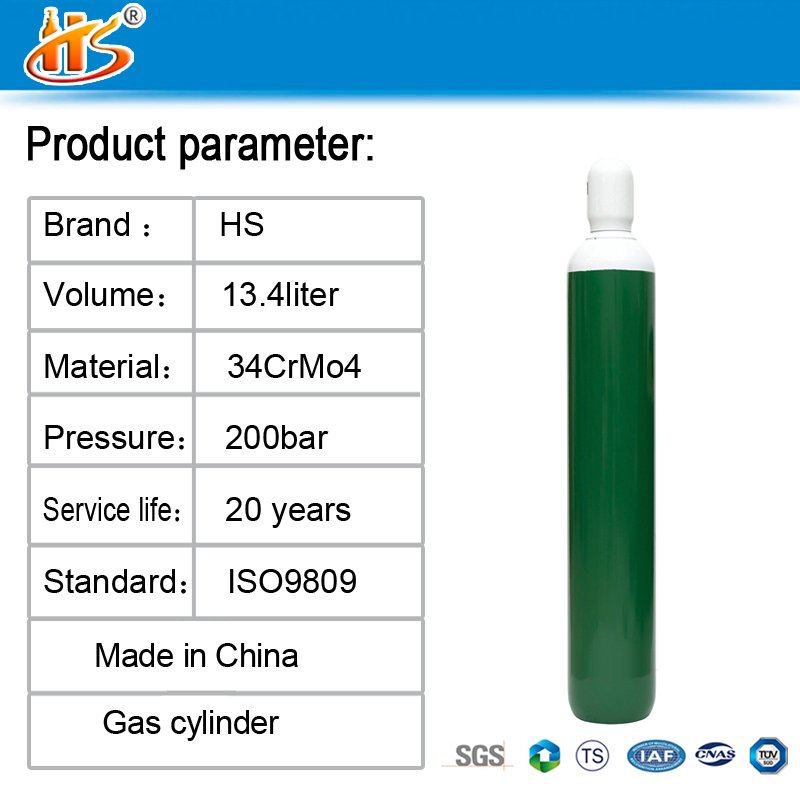

13.4L200ba CO2 Argon Réservoirs Azote Hélium N2O Bouteille d'air

Leak test of gas tanks:

The manufacturer shall employ such manufacturing techniques and apply such tests as will demonstrate to the satisfaction of the inspector that the cylinders do not leak.

1、Minimum de commande : 100 seulement

2、For cylinders with base ends formed by spinning, the following are three examples of typical testing procedures:

⎯ a pneumatic leakage test where the bottom end shall be clean and free from all moisture on the test pressure side.

The inside area of the cylinder bottom surrounding the closure shall be subjected to a pressure equal to at least two thirds of the test pressure of the cylinder for a minimum of 1 min;

This area shall be not less than 20 mm in diameter around the closure and at least 6% of the total bottom area.

3、The opposite side shall be covered with water or another suitable medium and closely examined for indication of leakage; cylinders that leak shall be rejected;

⎯ a low pressure pneumatic test;

⎯ a helium leak test.

4、13.4L 200ba CO2 Argon Tanks Nitrogen Helium N2O Air Cylinder (ISO9809-1 TPED 200BAR)

| Type | A l'extérieur

Diamètre (mm) |

L'eau

Capacité (L) |

Bouteille

Hauteur (mm) |

Poids

(kg) |

Travailler

pression (Bar) |

Mur de conception

l'épaisseur (mm) |

Matériau

Notes |

| WMAⅡ140-13.4L-200 | 140 | 13.4 | 1069 | 15.5 | 200 | 3.1 | 34CrMo4 |

| WMAⅡ159-13.4L-200 | 159 | 13.4 | 861 | 15.4 | 200 | 3.5 | 34CrMo4 |

| WMAⅡ180-13.4L-200 | 180 | 13.4 | 721 | 18.6 | 200 | 3.9 | 34CrMo4 |